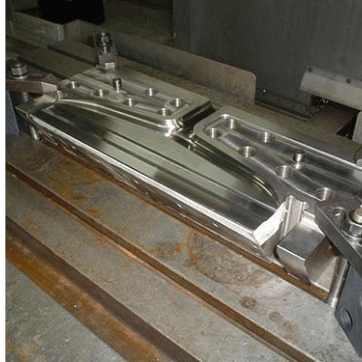

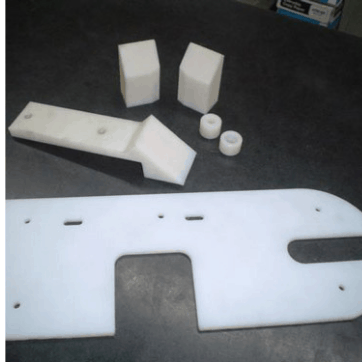

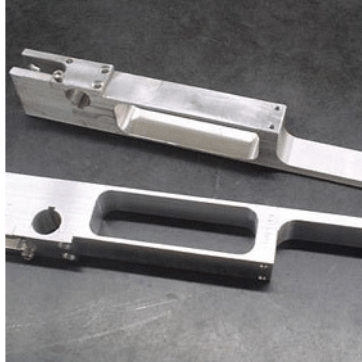

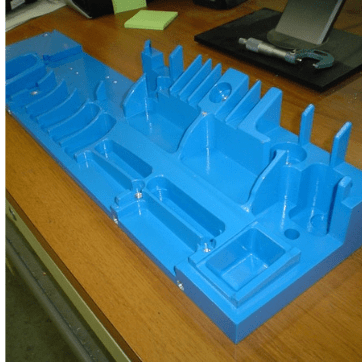

Our machining services include CNC Milling and Wire EDM along with a host of manually controlled support equipment including welders, plasma arc cutting, surface grinding, saws, sheet metal forming equipment, bead blasters, etc. Through partnerships, we are also able to provide CNC Lathe, Laser and Water jet cutting, centerless grinding, vibratory finishing, Anodizing, Cadmium and Chrome Plating, powder coating and heat treating.

This allows us to combine the most effective means and methods on complex parts that may require multiple machining methods. Also, if you have assemblies of multiple parts, we are well suited to make all the parts and assemble them for you. As we grow, we are adding more in house capabilities to better serve you.

Many of our customers supply their own drawings, but if you don’t have your own, we can take your ideas and turn them into parts using our in house CAD/CAM capabilities.

With our CNC Mills, we can process most most metals including, Aluminum, Stainless Steel, Copper, Steel, Brass, Bronze, etc., and other materials like, Nylon, Acetyl, Polycarbonate, Polystyrene, Acrylic, Fiberglass, Carbon fiber, PTFE, ABS, PVC, etc.

CNC MILLING CAPABILITIES

- Maximum Milled Part Size

40″ x 21.7″ x 21.7″

- Maximum Turned Part Size

20″ in Diameter and 80″ Long

- Standards

OSHA

- Design and Engineering Capabilities

2 Seat CAM

5 Seat CAD

- Industries Served

Vinyl Siding

Manufacturing

Packaging

Food

Equipment Specifications

- Hurco VM-30 Vertical CNC Milling Center

20 Station Tool Magazine

10,000 RPM Spindle

Travel of X-Axis 50″

Y-Axis 20″

Z-Axis 20″

- Mori Seiki MV-45 Vertical CNC Milling Center

24 Station Tool Magazine

Travel: X-Axis 30″, Y-Axis 17.7″, Z-Axis 19.7″

- Mori Seiki MV-55 Vertical Milling Center

24 Station Tool Magazine

Travel: X-Axis 40″, Y-Axis 21.7″, Z-Axis 21.7″