In many situations, automating a process is the best way to reduce costs and improve quality through consistency. At K-Ter Imagineering, we understand your need to succeed and work together with you to identify the parts of your process that are holding you back. We work with you to determine the best way to boost production speed and quality and seek to make the job easier and safe for your employees. This can be something as simple as a fixture or tool, an improved guard or as complex as a robot making and assembling parts. Whatever your needs, we will work with you to find the best solution and after the sale, we stand behind our work like no one else.

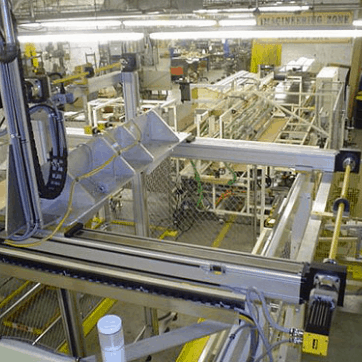

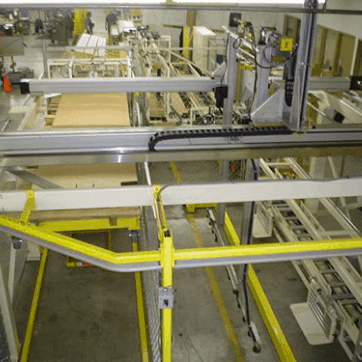

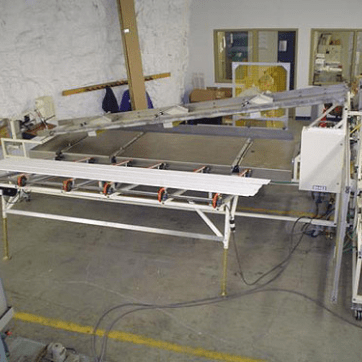

One area of specialization for us has been customized semi-automatic or automatic packaging machines for packaging large and unusual shaped parts. Our packaging equipment for the Vinyl Siding Industry comes with an integrated palletizing robot and consists of three other machines – a sorting table, packing conveyor, and box end-closing machine that closes and seals the ends of the box automatically.

The Sorting Table receives the siding panels and stacks them in the right order for packing in the Packing Conveyor. The Packing Conveyor folds the box around the Siding and seals the long edge as it conveys the box downstream. The ends of the box are sealed by the Box End Closing Machine and staged for palletizing by the integrated Palletizer. The custom Palletizer can be used with wood pallets or racks of any size and the boxes can be stacked in the best arrangement to maximize the load.

We have also designed and built a totally automatic packaging machine for vinyl siding capable of packaging sixty boxes per hour.

Every part of the packaging system is designed to maximize the safety for the packer, minimize the repetitive motion and increase the rate of production. Our customers have reaped the benefits of better quality packaging, fewer damaged goods, higher rates of production, and better employee retention.

MACHINE DESIGN FOR PRODUCTION AUTOMATION CAPABILITIES

- Packaging Equipment Configurations

Fully Automatic

Semi-Automatic

- Integrated Machines

Box End Closing Machine

Box Erecting Table

Packing Conveyor

Palletizer

Sorting Table

- Sorting Table Capabilities

Orientates panel either face up or face down according to stacking requirements

Receives the panel from the cut off machine and moves it toward the operator

- Packing Conveyor Capabilities

Conveys filled box to next machine while hot gluing the long edge of box

Folds box with packer’s assistance reducing repetitive motion

Pulls stack of panels toward operator reducing the operators reaching motion

Reduces glue usage and mess

- Box End Closing Machine Capabilities

Folds and seals ends of five panel end fold box

Positions box for proper orientation for palletizing

- Palletizer Capabilities

Allows users to use different size pallets and/or racks

Picks up completed boxes and places them on the pallet in assorted arrangements

Provides location of pallets

Stores completed boxes while filled pallet is removed and empty pallet is installed

User interface allows operator to scroll to correct program based on product

- Box Erecting Table Capabilities

Eliminates repetitive stress injuries, while improving box quality

Erects and over bends tube boxes up to 25′ long

Only two adjustments to change box sizes

- Machining Capabilities

CNC Vertical Machining

Grinding

Milling

Turning

Welding and Fabrication

Wire EDM

- Design and Engineering Capabilities

2 Seats CAM

5 Seats CAD

CadKey

Solidworks 2012

MasterCam 16

- Industries Served

Vinyl Siding

Manufacturing

Packaging

Food

Gas Meter

1st Tier Automotive

Equipment Specifications

- Hurco VM-30 Vertical CNC Milling Center

20 Station Tool Magazine

10,000 RPM Spindle

Travel of X-Axis 50″

Y-Axis 20″

Z-Axis 20″

- Mori Seiki MV-45 Vertical CNC Milling Center

24 Station Tool Magazine

Travel: X-Axis 30″, Y-Axis 17.7″, Z-Axis 19.7″

- Mori Seiki MV-55 Vertical Milling Center

24 Station Tool Magazine

Travel: X-Axis 40″, Y-Axis 21.7″, Z-Axis 21.7″

- Mitsubishi Model FX20 - Wire EDM

Auto Wire Feed

Axes: 4

Maximum Weight: 1764 lbs

Work Envelope: X-Axis 19.2, Y-Axis 13.8, Z-Axis 11.8

- Mitsubishi Model DWC110 C2 - Wire EDM

Axes: 4

Maximum Weight: 1100 lbs

Work Envelope: X-Axis 11.8, Y-Axis 17.7, Z-Axis 10.0