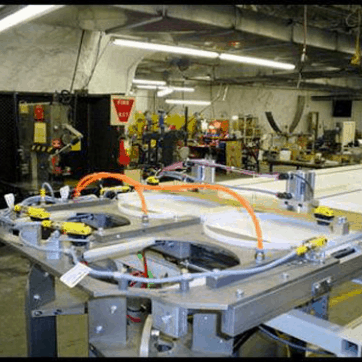

At K-Ter Imagineering Inc., our goal is to provide solutions that make your production better, easier, safer and more profitable. This is often done with upgrades, repairs and modifications to existing equipment. Imagineering allows us to provide you with improved ergonomic features, to make the operation easier and safer, improving employee retention and satisfaction while boosting quality and productivity at the same time.

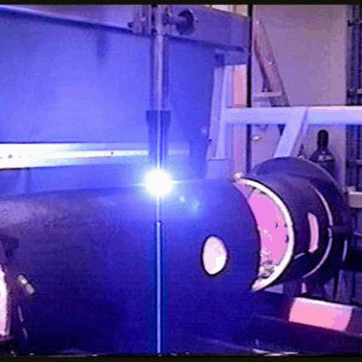

Our machinery modification services are open for all types of automation projects, be it adding a totally new machine/method or modifying an existing operation. For instance, if you need to increase the effectiveness of your existing packaging system or replace an ineffective machine with a new one, we’re here to help you. K-TER has helped many customers increase their line speed as well as decrease scrap and down time.

Past customers have included the United States Postal Service, CertainTeed, Owens Corning, Plygem Building Products, FAG Bearing, Henkel to name a few. We pride ourselves on our commitment to satisfying your needs!

EXISTING MACHINE MODIFICATION CAPABILITIES

- Automation

Electrical

Mechanical

PLC programming

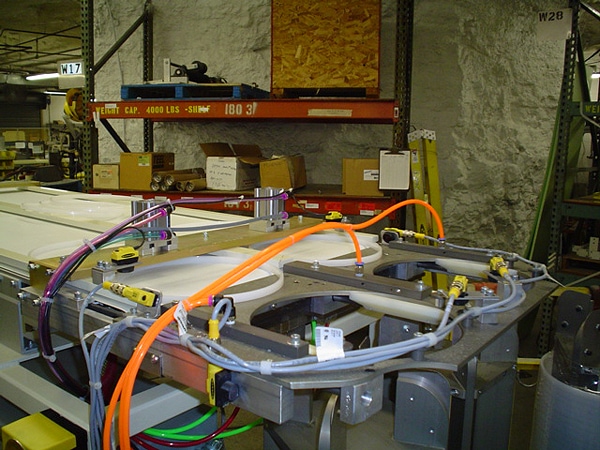

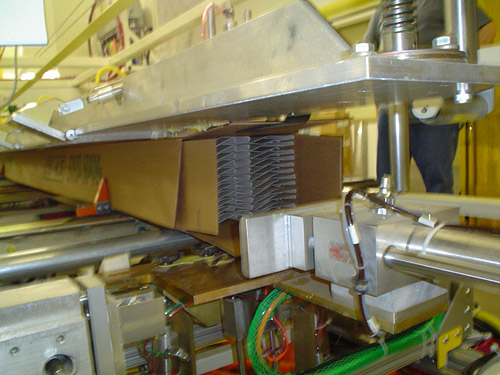

Pneumatic and Hydraulic Control Systems Engineered and Built

- Safety Guarding Options

Labels that warn of missing guards

OSHA standards

Proper fusing and grounding

Safety color coded parts

Safety disconnects for all sources of power

Safety interlocks on critical guards

- Other Features

All stainless steel water plumbing

Forklift straps on the frames

Powder coating

Rail mounted machinery

Stainless steel guards

- Custom Specialty Machines

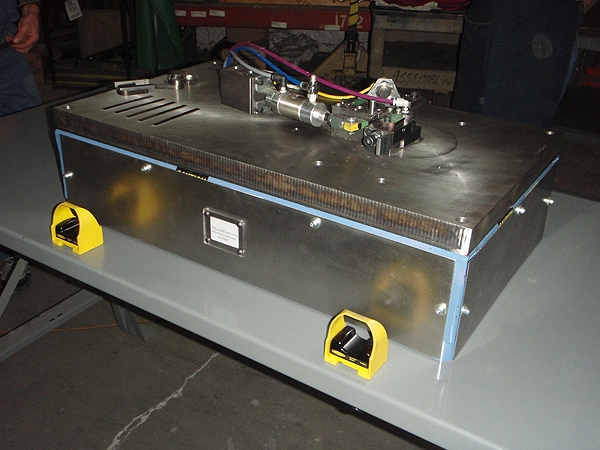

Gas Meter Assembly & Inspection

Automotive Head Liner & Seat Assembly

Ice Cream Bucket Assembly Machine

- Assembly Capability

10,000 Sq. Ft. of Assembly Space

- Design and Engineering Capabilities

2 Seats CAM

5 Seats CAD

CadKey

Solidworks 2012

MasterCam 16

- Machining Capabilities

CNC Vertical Machining

Grinding

Milling

CNC Vertical Machining

Grinding

Milling

- Part Specifications

Milling: 20″ x 50″

Surface Grinding: Up To 12″ x 24″

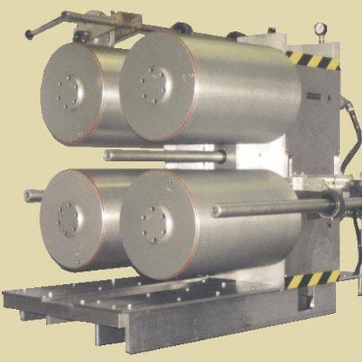

Turning: Up To 21″ Diameter x 80″ Long

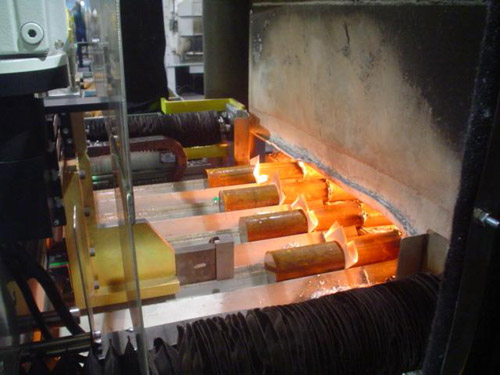

- Industries Served

Vinyl Siding

Manufacturing

Packaging

Food

Gas Meter

1st Tier Automotive

EQUIPMENT SPECIFICATIONS

- Hurco VM-30 Vertical CNC Milling Center

20 Station Tool Magazine

10,000 RPM Spindle

Travel of X-Axis 50″

Y-Axis 20″

Z-Axis 20″.

- Mori Seiki MV-45 Vertical CNC Milling Center

24 Station Tool Magazine

Travel: X-Axis 30″, Y-Axis 17.7″, Z-Axis 19.7″

- Mori Seiki MV-55 Vertical Milling Center

24 Station Tool Magazine

Travel: X-Axis 40″, Y-Axis 21.7″, Z-Axis 21.7″

- Mitsubishi Model FX20 - Wire EDM

Auto Wire Feed

Axes: 4

Maximum Weight: 1764 lbs

Work Envelope: X-Axis 19.2, Y-Axis 13.8, Z-Axis 11.8

- Mitsubishi Model DWC110 C2 - Wire EDM

Axes: 4

Maximum Weight: 1100 lbs

Work Envelope: X-Axis 11.8, Y-Axis 17.7, Z-Axis 10.0